CORDOVA, Ala. – North Alabama continues to play a big role in helping America return to human deep-space exploration. On Thursday, August 31, local companies celebrated the completion of a massive piece of equipment that will help get us there.

“The Pathfinder has a very simple job when you get right down to it,” said Julie Bassler, Deputy Manager for the SLS Stages Office at NASA’s Marshall Space Flight Center. “It will prevent us from saying… “OOPS” when it comes to moving our first important SLS core stage.”

Dozens of people from different companies and NASA attended the event to see the SLS Core Stage Pathfinder in person. The Pathfinder will soon be on its way to help NASA facilities perform important tests. It’s a full-scale mockup made to be similar to the real Core Stage in shape, size and weight. When we say it’s big, check the measurements:

• It weighs 228,000 pounds

• It’s 27.6 feet in diameter

• It’s 212 feet long

The Pathfinder will let NASA practice on non-space flight hardware before the real rocketry is in place. Handlers can learn how to transport it, move it upright, and how to house it in different facilities and perform tests on it. This way, when they get the real Core Stage shipped to them, they’ll have already worked out the kinks.

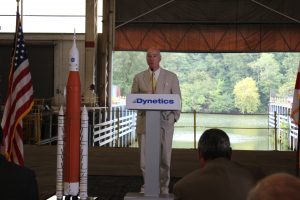

“It’s fitting we have this ceremony to mark the completion,” said Congressman Robert Aderholt. “It’s good to find what adjustments need to be made ahead of time. When people ask, why would we spend millions of dollars on this? It’s a simple answer. What will be on this will be our most precious cargo that we have in the United States — our American astronauts.”

Dave King, CEO of Dynetics, points to the area on a SLS model showing where the Core Stage ends. This model is 1/50th of the size of what the real rocket will be. (Photo: Claire Aiello)

Dynetics played a big role in the completion of the Pathfinder. NASA awarded Radiance Technologies the pathfinder vehicle delivery order under the Engineering Solutions and Prototyping contract with Dynetics as the technical lead.

“Thanks to NASA and Marshall Space Flight Center for trusting us to do this and selecting our team,” said Bill Bailey, CEO of Radiance Technologies. “I grew up in a small Alabama town, Ashville, and I was awestruck with all the things that were happening, and Alabama is still playing a large role in the space program today.”

“This project has been a true testament to the willingness and innovative spirit of so many engineers and technicians in north Alabama to provide NASA with an article that can be used to before the real core stage arrives at Kennedy Space Center in a few years,” said Robert Wright, Dynetics Deputy Division Manager for Space.

Dave King, Dynetics’ Chief Executive Officer, echoed those sentiments.

“North Alabama is known for doing difficult engineering in an effort to advance the future of space exploration. The Marshall Space Flight Center and Redstone Arsenal provide for many opportunities for our district to build space hardware,” said King. “We heard about the Launch Vehicle Stage Adapter completion earlier this week, our own Dynetics Aerospace Structures Complex announcement and now pathfinder. North Alabama is well positioned to provide space hardware for years to come.”

Dynetics is also developing the Universal Stage Adapter for the SLS. NASA named the company prime contractor in June.

Bret Guest, Vice President of G&G Steel, stands in front of the ‘Spider’ – the large piece of steel that will cover the Core Stage. (Photo: Claire Aiello)

For the Core Stage Pathfinder, G&G Steel was added to perform the final welding and major assembly operations in their commercial facility in Cordova, located in Winston County. Bret Guest is the company’s Vice President and touched on Russellville High School’s accomplishments during his remarks. In 2015, the team won an international rocketry challenge.

He said the students’ success inspired the entire community. He also recognized his employees. “They worked and sweated for long hours to make this happen,” Guest said.

G&G’s facility is on the Black Warrior River, and water access is critical because the Core Stage Pathfinder will be moved by barge later this month. It will travel to the Michoud Assembly Facility in New Orleans. Later, it will be moved to Stennis Space Center and Kennedy Space Center on NASA’s Pegasus barge.

The companies began the work on the Core Stage Pathfinder in early 2016. Having large components to test is vital to the mission, according to NASA’s Bassler.

“I am sure many of you know that college football is about to kick off another great season and a big part of the excitement is the intense competition. But another big part is the teamwork that is required to play the game at the highest level,” Bassler explained. “It also demands teamwork to do human space exploration. Many NASA centers are playing a part in our new effort to return to the moon and go on to Mars. For SLS alone, it involves more than 1,000 manufacturers and suppliers. We’re here today to celebrate another important touchdown thanks to our core stage Pathfinder teammates.”

NASA’s SLS will be the largest rocket ever built. The core stage will weigh 2.3 million pounds once it’s filled with propellant.

-

- These are placeholders for the engines at the bottom of the Core Stage Pathfinder. (Photo: Claire Aiello)

-

- Team members from Radiance Technologies, Dynetics, G&G Steel and Barnhart Crane and Rigging pose for a photo with Congressman Robert Aderholt. (Photo: Claire Aiello)

-

- The Core Stage Pathfinder is 212 feet long and weighs 228,000 pounds. It will be shipped on a barge to Michoud Assembly Facility in New Orleans. (Photo: Claire Aiello)

-

- Julie Bassler, Deputy Manager for the SLS Stages Office at MSFC, talks about the importance of teamwork on a project of this scale. (Photo: Claire Aiello)

-

- Bill Bailey, CEO of Radiance Technologies, touched on his team’s role in the job. (Photo: Claire Aiello)

-

- Congressman Robert Aderholt congratulates the workers who made the Core Stage Pathfinder a reality. He represents Alabama’s Fourth District, where the G&G Steel facility is located in Winston County. (Photo: Claire Aiello)